Technology

Tech

1. Biogas Technology

Biogas:

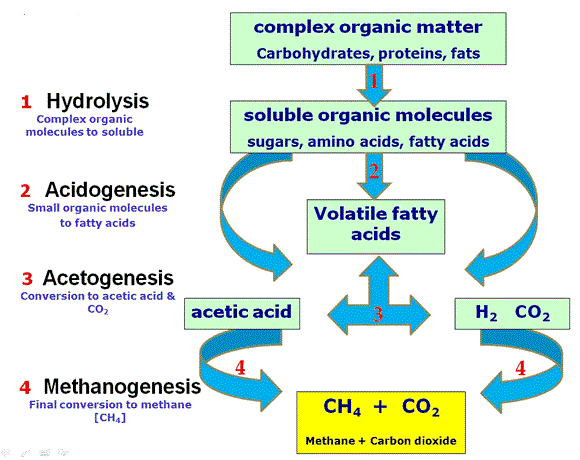

Biogas is a renewable and clean energy carrier with a calorific value of 21 – 37.5 MJ/m3 and is made up of a composition of several gases, namely: Methane (CH4), Carbon dioxide (CO2), Hydrogen Sulphide (H2S), Water vapour (H2O), Ammonia (NH3), Carbon monoxide (CO), Nitrogen (N2), Oxygen (O2) and Hydrogen (H2) [6] [7]. It is produced from the digestion of organic waste by microorganisms via the anaerobic process. The anaerobic process is made of four stages: hydrolysis, acidogenesis, acetogenesis and methanogenesis, with different groups of microorganism participating at each stage of the process. The principle of the anaerobic process is influenced by environmental conditions, solid content of organic material used, and the type of physical technology used. Thus the process and technology may be grouped into categories

** Biogas process**

Microbiology:

The process of anaerobic digestion of organic matter involves the microbially mediated conversion of complex organic matter into methane & CO2as final carbon mineralized products. The overall process involves defined carbon and electron flow pathways for the metabolism of diverse complex organic substrates into simple carbon products.

The use of carbon tracer studies and isolation of prevalent species and bacterial characterization studies have resulted in a very good quantitative picture of carbon flow. The process involved is carried out in three steps viz; Hydrolysis, Acidogenesis, Acetogenesis & finally Methanogenesis.

Applications:

a. Thermal applications

Biogas is produced from a variety of waste. Thus, it can be used by a small farmer & also can fulfill the thermal needs of industries. Particularly, industries producing organic waste can generate biogas of high quantum & with that can fulfill their energy needs either by burning the gas in boilers or through other means.

b. Electricity application

Biogas based power generation is another route of biogas utilization. Electricity can be generated though biogas engines or via boiler-turbine configuration. Biogas engines are available in wide range from few kW’s to several MW’s.

c. Bio-CNG (Automotive purpose)

Cleaned & upgraded biogas can be used for automotive applications. It is commercially viable to use H2Sfree biogas upgraded to more than 95 percent methane content for vehicular use. The cost of Bio-CNG production is comparatively much lower to the conventional fuels such as petrol, diesel, CNG, etc.

2. Technology Description:

Treatment Philosophy: Feed preparation/pretreatment

The waste truck sunload the Segregated Organic Solid Waste into Bin Unloading Unit which is in a waste reception area. The bin unloading unit has storage capacity of about one day and is providing unloading place for trucks.The Segregated Organic Solid Waste will be manually fed to the pre-treatment hopper. The Bin unloading unit is acting as an intermediate storage system that allows continuous feeding of the pretreatment unit.

Portion of Centrate / Digestate is pumped to pre-treatment system to adjust the moisture content

The segregated organic solid waste shall be processed through shredder and further pretreatment operation shall be carried out at Feed preparation tank. This tank will also act as inlet for main digester. The main function of the pre-treatment system is to disintegrate segregated Organic Solid Waste to maximize the biogas yield in the digester.

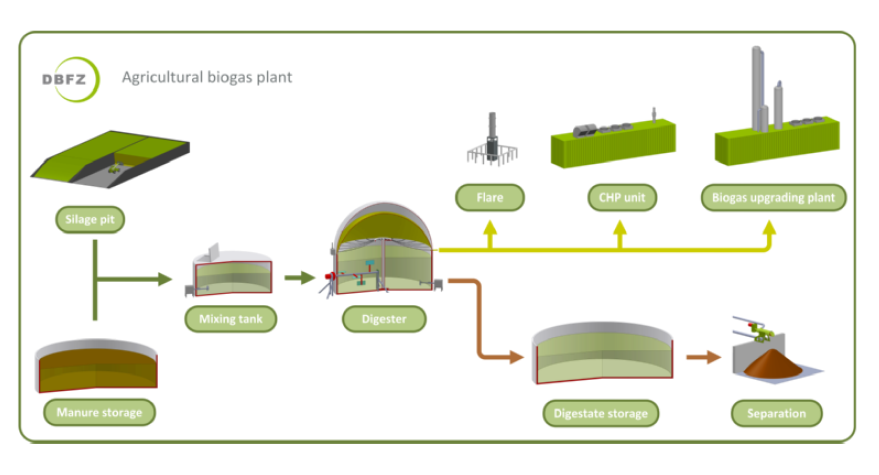

Fig.: General working of biogas digester

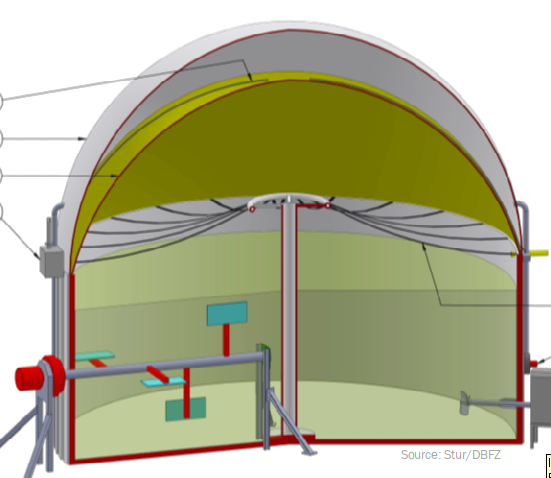

Main Digester:

A flexible dome biogas digester of 190 m3 is designed to treat the available waste of 2000 Kg/day segregated organic solid waste. The digester is designed assuming a retention period of 30 days. The construction will be above ground. It runs on a continuous basis.

Pre-treated combined slurry (Segregated Organic Solid Waste) is pumped into the digester for anaerobic degradation of Organic waste. This digester is working under mesophilic conditions (Temp. 37to42°C) for maximum degradation of Organic waste and Biogas production.

The mixing of the completely insulated digester is done with the stirrer and additionally with recirculation pump. The temperature in the digester is adjusted by an external heat exchanger. The temperature inside the digester is continuously controlled by a temperature measurement and it is maintained by digester heating system.

The digester is equipped with a vacuum cum pressure relief valve and liquid level indicator.

Flare Stack:

As a safety installation the biogas flare is integrated in the biogas line. If the maximum fill level is reached in the biogas storage tank, surplus biogas will be flared in Flare stack

Biogas Balloon:

Biogas Balloon for storage of Biogas generated

Desulphurization:

The first treatment step of the produced biogas is desulphurization using scrubber. H2S present in Biogas is acidic in nature and will corrode the biogas pipeline and the Biogas burners, hence a scrubber is provided to reduce H2S from the Biogas generated from digester.

Biogas Genset:

After removing H2S gas & Moisture content, biogas can be used for electricity generation.

Digested Sludge:

The Digested sludge (@ 5-7% Solids concentration) discharged from Digester is very rich in Nitrogen and phosphorous content and can be utilized as solid organic fertilizer for gardening / plantation. Part of the concentrate from the centrifuge will be recycled to Pre-treatment unit and balance can be sent to decentralized sewage treatment plant.